文章目录 [隐藏]

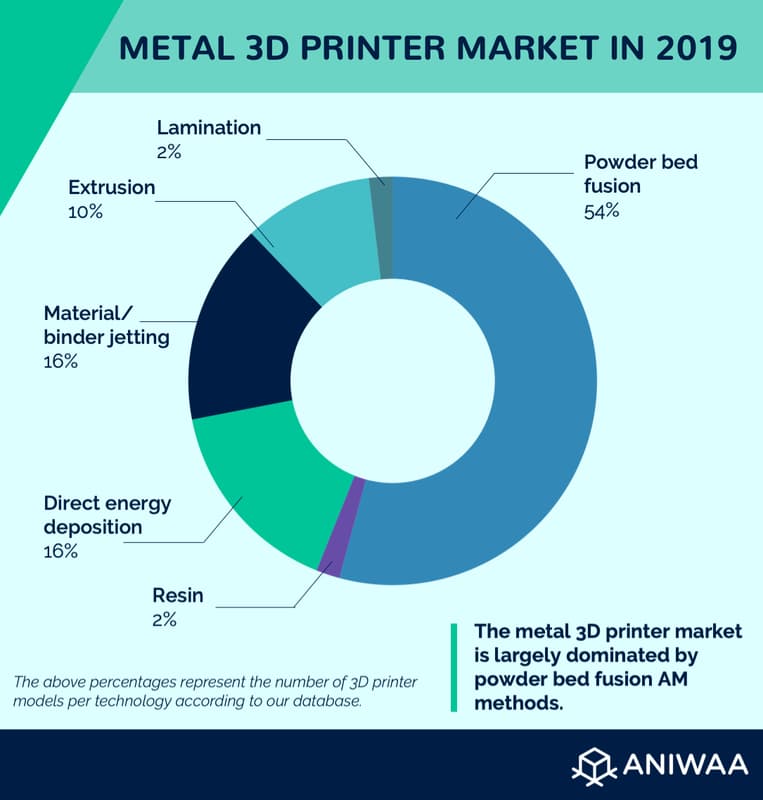

Metal 3D Printer market in 2019

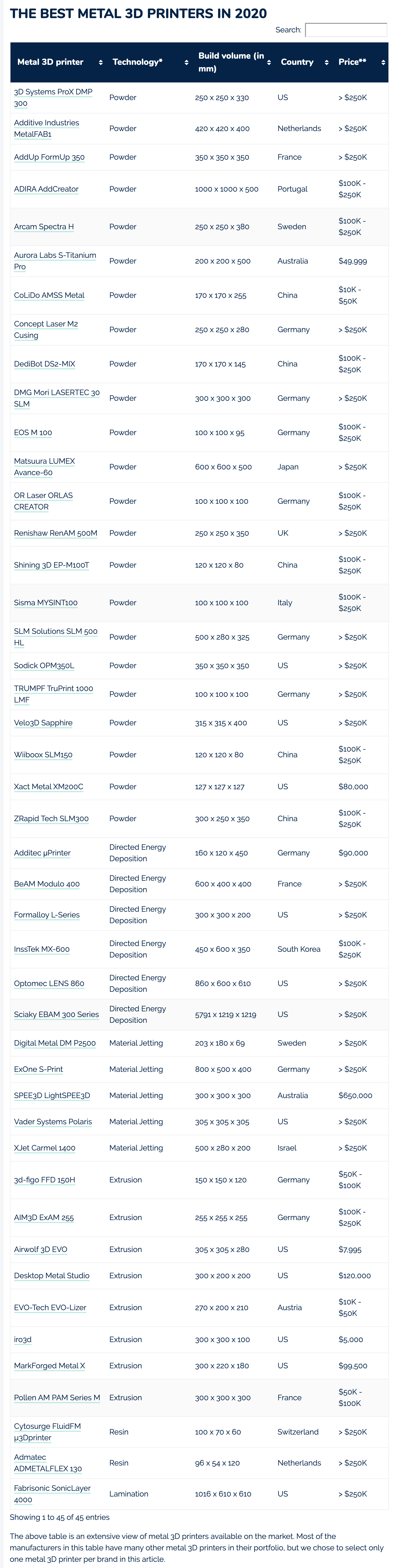

The best metal 3D printers in 2020

See How The New HP Metal Jet Technology Works

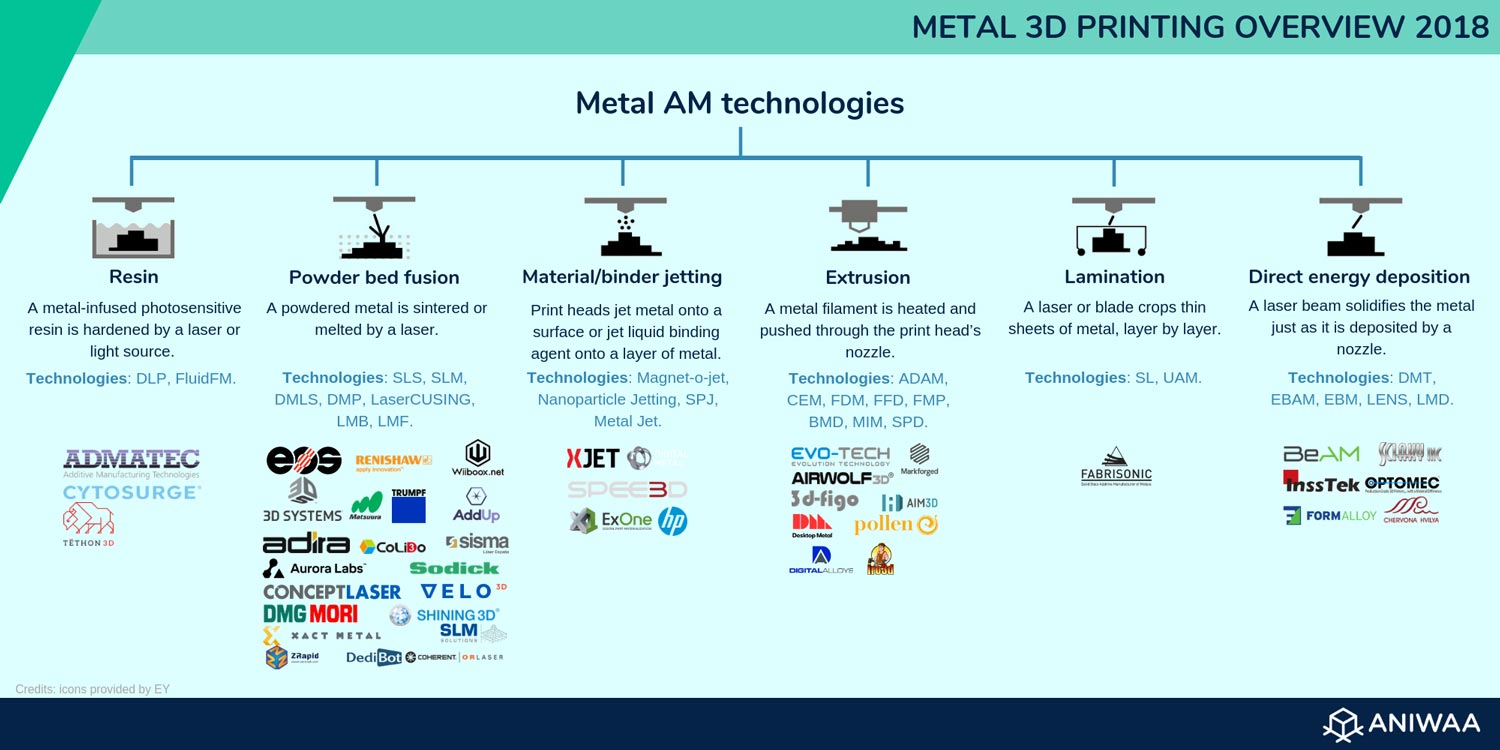

Metal 3D printing technologies

Many manufacturers develop their own variations of existing technologies and label them with different or modified names:

- Powder Bed Fusion (PBF): DMLS (Direct Metal Laser Sintering), DMP (Direct Metal Printing), LaserCUSING, LBM (Laser Beam Melting), LMF (Laser Metal Fusion), SLS (Selective Laser Sintering), SLM (Selective Laser Melting)

- Directed Energy Deposition (DED): DMT (Direct Metal Tooling), EBAM (Electron Beam Additive Manufacturing), EBM (Electron Beam Melting), LENS (Laser Engineered Net Shaping), LMD (Laser Metal Deposition)

- Metal Material Jetting (MJ) or Binder Jetting (BJ): Magnet-o-Jet, Nanoparticle Jetting, SPJ (Single Pass Jetting), Metal Jet

- Metal filament extrusion/Fused Filament Fabrication (FFF): ADAM (Atomic Diffusion Additive Manufacturing), CEM (Composite Extrusion Modeling), FDM (Fused Deposition Modeling), FFD (Fused Feedstock Deposition), FMP (Filament Metal Printing), BMD (Bound Metal Deposition), MIM (Metal Injection Molding)

- Lamination: SL (Sheet Lamination), UAM (Ultrasonic Additive Manufacturing)

- Metal resin 3D printing: DLP (Digital Light Processing), FluidFM, SLA (Stereolithography)

Metal 3D printing services

Sculpteo

Shapeways

3D Hubs

Stratasys

i.materialise

Protolabs

Benefits and limits of metal 3D printing

Metal 3D printer benefits

- High-quality parts and prototypes

- Precision and accuracy

- On-demand production

- Ability to 3D print complex geometries

- Waste reduction compared to traditional methods

Limits of metal 3D printers

- Large footprint

- Learning curve

- Expensive hardware, material, and hidden costs (energy, time, etc.)

- afety precautions required for material handling